Published 04-06-2024

Keywords

- droplet drop off,

- droplet breakage,

- static atomization,

- liquid fuel

Copyright (c) 2024 Cambridge Science Advance

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

How to Cite

Abstract

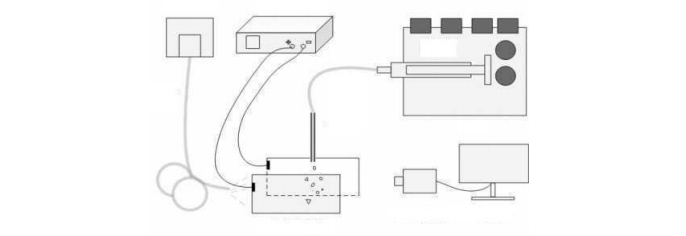

The study of electrostatic shedding and crushing characteristics of droplets is the basis of understanding electrostatic atomization, and the study of its shedding and crushing behavior in electrostatic field is conducted. Micropump drive is used to control the flow rate, electrostatic generation device to form a stable electric field, light lighting and high-speed camera to obtain the dynamic behavior of shedding and crushing process, and use digital image processing technology to extract the process parameters. The results show that: when the capillary tube diameter and flow are unchanged, when the electric field voltage is low, the droplet deviates and falls off, the diesel droplet is smaller than the ethanol; when the electric field voltage is moderate, the droplet is closed or deformed into wave strip; only when the flow rate increases and the electric field voltage is large, the average particle size of ethanol is smaller than diesel, indicating that the electrostatic atomization effect of ethanol with small surface tension is significantly better than that of diesel oil.

References

- KOHLERJ, BEJHEDJ, KRATZ H, et al. A hybrid cold gas micro thruster system for spacecraft [J]. Sensors & Actuators A Physical, 2002,97(1) :587-598. DOI: https://doi.org/10.1016/S0924-4247(01)00805-6

- KERECHANIN C W, SAMIMY M, KIM J H. Effects of nozzle trailing edges on acoustic field of supersonic rectangular AIAA Journal, 2001,39(6) :1065-1070. DOI: https://doi.org/10.2514/2.1418

- REED BD W, DANG L. Experimental evaluation of cold flow micronozzles [C]/37th Joint Propulsion Conference and Exhibit.2001 :3521. DOI: https://doi.org/10.2514/6.2001-3521

- WILM M, SHEVCHENKO A, HOUTHAEVE T, et al. Femtomole sequencing of proteins from polyacrylamide gels by nano-electrospray mass spectrometry [J]. Nature, 1996,379(6564) :466-469. DOI: https://doi.org/10.1038/379466a0

- TAKATS Z, WISEMAN J M, GOLOGAN B, et al. Mass spectrometry sampling under ambient conditions with desorption electrospray ionization[J]. Science, 2004,306(5695):471-473. DOI: https://doi.org/10.1126/science.1104404

- KAISER S, KYRITSIS D C, DOBROWOLSKI P, et al. The electrospray and combustion at the mesoscale[J]. Journal of the Mass Spectrometry Society of Japan, 2003,51(1):42-49. DOI: https://doi.org/10.5702/massspec.51.42

- JAWOREK A. Micro and nanoparticle production by electro spraying[J]. Powder Technology, 2007,176(1): 18-35. DOI: https://doi.org/10.1016/j.powtec.2007.01.035

- HIGUERA F J. Neutralization of a spray of electrically charged droplets by a corona discharge[J]. Journal of Fluid Mechanics, 2016,801:130-149. DOI: https://doi.org/10.1017/jfm.2016.449

- WATANABE H, MATSUYAMA T, YAMAMOTO H. Experimental study on electrostatic atomization of highly viscous liquids[J]. Journal of Electrostatics, 2003,57(2) : 183-197. DOI: https://doi.org/10.1016/S0304-3886(02)00139-0

- DU W, CHAUDHURI S. A multi physics model for charged liquid droplet breakup in electric fields [J]. International Journal of Multiphase Flow, 2017,90 :46-56. DOI: https://doi.org/10.1016/j.ijmultiphaseflow.2016.11.009

- HUO Y, WANG J, ZUO Z, et al. Visualization of the evolution of charged droplet formation and jet transition in electrostatic atomization[J]. Physics of Fluids, 2015,27(11) :2192-2211. DOI: https://doi.org/10.1063/1.4935881

- MAAB S, KRAUME M. Determination of breakage rates using single drop experiments. Chemical Engineering Science 2012,70: 146-164. DOI: https://doi.org/10.1016/j.ces.2011.08.027