Published 26-01-2024

Keywords

- micron-sized aluminum powder,

- oxidized environment,

- thermogravimetric analysis,

- oxidation mechanism

Copyright (c) 2024 Cambridge Science Advance

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

How to Cite

Abstract

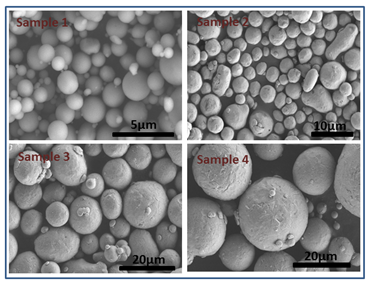

The behavior of aluminum powders in specific oxidized environment is different from each other obviously. Thermal behaviors of micron-sized aluminum powders in different oxygenated and gradually heating environments were discussed in order to find out the oxidation mechanism. Particular attention is paid to the reaction mechanism of oxygen and carbon dioxide atmosphere. Thermogravimetric analysis and related characterization methods are used and the results demonstrated that under the certain condition, reaction process of micron-sized aluminum powders can be divided into four stages. General routes for the oxidation of micron-sized aluminum in general heating system are the same, however, itis different among the extent of reaction at the third stage in different kinds of oxidizing gas atmospheres. Gas phased products were detected during the main reaction stage under carbon dioxide by combining thermal analysis and mass spectrometry which contributes to the rupture of alumina shell and further reaction of micron-sized aluminum powders. Consequently, rapider and more complete reaction process was achieved. The increasing thickness of original alumina shell can restrict the reaction rate of aluminum powders harder at the same time.

References

- Stamatis, D., et al., Aluminum burn rate modifiers based on reactive nanocomposite powders. Propellants, Explosives, Pyrotechnics, 2010. 35(3): p. 260-267.

- Valliappan, S., J. Swiatkiewicz, and J.A. Puszynski, Reactivity of aluminum nanopowders with metal oxides. Powder Technology, 2005. 156(2–3): p. 164-169.

- Widener, J. and M. Beckstead, Aluminum combustion modeling in solid propellant combustion products. AIAA paper, 1998. 3824: p. 1998.

- Escot Bocanegra, P., et al., Experimental and numerical studies on the burning of aluminum micro and nanoparticle clouds in air. Experimental Thermal and Fluid Science, 2010. 34(3): p. 299-307.

- Huang, Y., et al., Combustion of bimodal nano/micron-sized aluminum particle dust in air. Proceedings of the Combustion Institute, 2007. 31(2): p. 2001-2009.

- Badiola, C., R.J. Gill, and E.L. Dreizin, Combustion characteristics of micron-sized aluminum particles in oxygenated environments. Combustion and flame, 2011. 158(10): p. 2064-2070.

- Gan, Y. and L. Qiao, Combustion characteristics of fuel droplets with addition of nano and micron-sized aluminum particles. Combustion and flame, 2011. 158(2): p. 354-368.

- Puri, P. and V. Yang. Thermo-mechanical behavior of nano aluminum particles with oxide layers. in 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV. 2008.

- Risha, G.A., et al., Combustion and conversion efficiency of nanoaluminum-water mixtures. Combustion Science and Technology, 2008. 180(12): p. 2127-2142.

- Risha, G.A., et al., Combustion of nano-aluminum and liquid water. Proceedings of the Combustion Institute, 2007. 31(2): p. 2029-2036.

- Xiaoying Zhu, M.S., Edward L. Dreizin, Oxidation of Aluminum Particles in Mixed CO2H2O Atmospheres. 2010.

- Xiaoying Zhu, M.S., and Edward L. Dreizin, Aluminum Powder Oxidation in CO2 and Mixed CO2O2 Environments. 2009.

- Zhang, S., M. Schoenitz, and E.L. Dreizin, Nearly Pure Aluminum Powders with Modified Protective Surface. Combustion Science and Technology, 2013. 185(9): p. 1360-1377.

- Trunov, M.A., et al., Effect of polymorphic phase transformations in Al2O3 film on oxidation kinetics of aluminum powders. Combustion and Flame, 2005. 140(4): p. 310-318.

- Rufino, B., et al., Influence of particles size on thermal properties of aluminium powder. Acta Materialia, 2007. 55(8): p. 2815-2827.

- Starink, M.J., The analysis of Al-based alloys by calorimetry: quantitative analysis of reactions and reaction kinetics. International Materials Review, 2004. 49(4): p. 191-226.

- Trunov, M.A., et al., Effect of polymorphic phase transformations in Al< sub> 2 O< sub> 3 film on oxidation kinetics of aluminum powders. Combustion and flame, 2005. 140(4): p. 310-318.

- Trunov, M.A., M. Schoenitz, and E. Dreizin, Effect of polymorphic phase transformations in alumina layer on ignition of aluminium particles. Combustion Theory and Modelling, 2006. 10(4): p. 603-623.

- Maggi, F., et al., Activated aluminum powders for space propulsion. Powder Technology, 2015. 270: p. 46-52.

- Dreizin, E.L., Experimental study of stages in aluminium particle combustion in air. Combustion and flame, 1996. 105(4): p. 541-556.