Published 26-01-2024 — Updated on 26-01-2024

Keywords

- atomized Al-Mg alloy powder,

- thickness of oxide shell,

- active Al-Mg,

- size distribution

Copyright (c) 2024 Cambridge Science Advance

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

How to Cite

Abstract

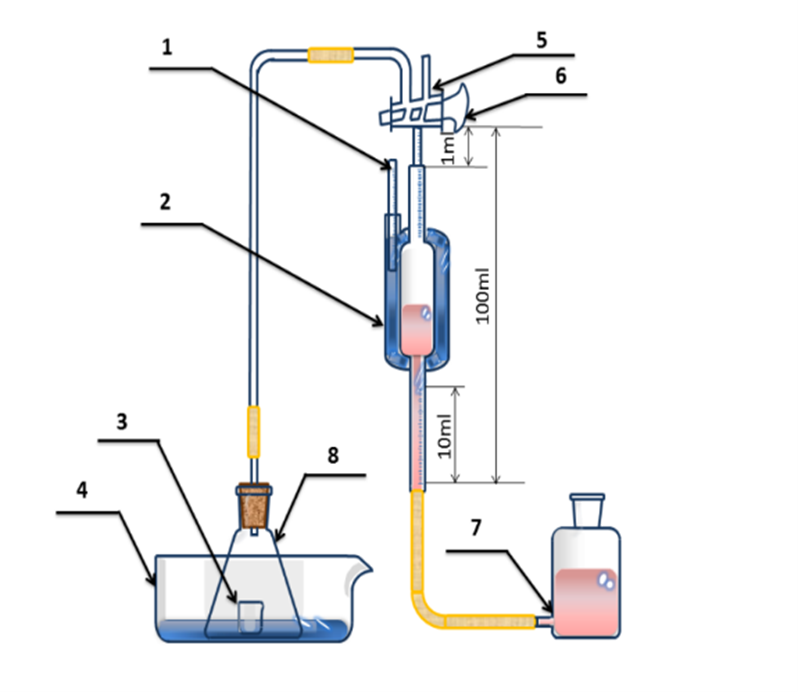

The empirical formula of average oxide thickness of atomized micron-sized aluminum - magnesium alloy powder was proposed. At the same time, the influence of particle size and the ratio of magnesium on samples’ activity was studied. The phase composition, morphology, and oxidation process of the alloy powders were studied by x-ray diffraction, scanning electron microscope/energy-dispersive x-ray, respectively. Study on the change of powder activity was achieved by standard gas volumn method. The results show that the oxide thickness of the atomized micron-sized aluminum - magnesium alloy powder is positively correlated with the particle size, and the activity decreases with the increase of the particle size and the magnesium content.

References

- Moussa, R.B., et al., Physical mechanisms involved into the flame propagation process through aluminum dust-air clouds: A review. Journal of Loss Prevention in the Process Industries, 2017. 45: p. 9-28.

- Pisharath, S., F. Zhang, and H.G. Ang, Influence of passivation on ageing of nano-aluminum: Heat flux calorimetry and microstructural studies. Thermochimica Acta, 2016. 635: p. 59-69.

- Starik, A.M., A.M. Savel’ev, and N.S. Titova, Specific features of ignition and combustion of composite fuels containing aluminum nanoparticles (Review). Combustion, Explosion, and Shock Waves, 2015. 51(2): p. 197-222.

- Schreiber, S., G. Theodossiadis, and M. Zaeh. Combustion synthesis of reactive nickel-aluminum particles as an innovative approach for thermal joining applications. in IOP Conference Series: Materials Science and Engineering. 2017. IOP Publishing.

- Xie, G., et al., Behavior of Oxide Film at Interface between Particles of Al-Mg Alloy Powder Compacts Prepared by Pulse Electric Current Sintering. Japanese Journal of Applied Physics, 2003. 42(42): p. 4725-4728.

- Xie, G., et al., Reduction mechanism of surface oxide films and characterization of formations on pulse electric-current sintered Al–Mg alloy powders. Applied Surface Science, 2005. 241(1–2): p. 102-106.

- 曾亮, et al., 微米铝粉活性及氧化膜厚度研究 [J]. 北京理工大学学报, 2012. 2: p. 020.

- Aly, Y. and E.L. Dreizin, Ignition and combustion of Al·Mg alloy powders prepared by different techniques. Combustion & Flame, 2015. 162(4): p. 1440-1447.

- Nie, H., M. Schoenitz, and E.L. Dreizin, Oxidation of differently prepared Al-Mg alloy powders in oxygen. Journal of Alloys & Compounds, 2016. 685: p. 402-410.