Study on the oxidation mechanism of micron- and nano-sized aluminum powders influenced by alumina shell

Published 26-01-2024

Keywords

- aluminum particles,

- core-shell structure,

- thickness of alumina shell,

- oxidation reaction,

- thermal analysis

Copyright (c) 2024 Cambridge Science Advance

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

How to Cite

Abstract

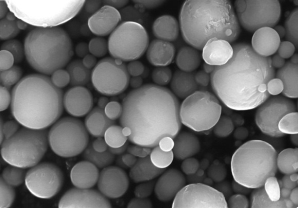

Thermal behaviors for aluminum particles at oxidative atmosphere gradually heating system were discussed. Heating micron- and nano-sized aluminum powders from room temperature to 1400℃ using thermal analysis method. The results showed that the reaction process for micron-sized aluminum particles can be divided into four stages which include the phase change of oxidized shell, increasing thickness of alumina shell, main broken shell oxidizing process and the phase change of alumina shell in high temperature. Thermal analysis for micro aluminum particles was carried out with shell thickness adjustments via ambient manual means. It turned out that the oxide layer thickness would have full limitation effects on the slow oxidation for micro aluminum particles with shell structure when it was increased above twice of the original thickness. The limitation effects of oxide shell thickness on the heating processes in gradually heating system were proposed. Humidity environment can make the thickness of alumina increase in a certain range when the particles are in nano-scale. Complete oxidation processes were observed but an increase of the oxidation temperature was identified.

References

- E. L. Dreizin and M. Schoenitz, "Progress in Energy and Combustion Science" 2015, 50, 81-105

- A. M. Starik, A. M. Savel’ev and N. S. Titova, "Combustion, Explosion, and Shock Waves" 2015, 51, 197-222

- D. S. Sundaram, V. Yang and V. E. Zarko, "Combustion, Explosion, and Shock Waves" 2015, 51, 173-196.

- F. Maggi, S. Dossi, C. Paravan, L. T. Deluca and M. Liljedahl, "Powder Technology" 2015, 270, 46-52.

- Zheng Guoqiang, Zhang Wenchao, Xu Xing, Shen Ruiqi, Deng Jiping, and Ye Yinghua, "Journal of Inorganic Materials" 2015, Vol. 30, 610–614.

- An Ting, Zhao Fengqi, Yi Jianhua, Fan Xuezong, Gao Hongxu, Hao Haixia, Wang Xiaohong, Hu Rongzu and Pei Qing, "Acta Physico-Chimica Sinica" 2011, 27, 281-288

- Zhu Yanli, Jiao Qingjie, Huang Hao and Ren Hui, "Chemical Journal of Chinese Universities" 2013, 34, 662-667

- Zeng Liang, Jiao Qingjie, Ren Hui and Zhou Qing, "Chinese Journal of Explosives & Propellants (Huozhayao Xuebao)" 2011, 34, 26-29

- V. Yang, D. Sundaram and P. Purl, "Proceedings of 2010"

- Y. S. Kwon, A. A. Gromov, A. P. Ilyin and G. H. Rim, "Applied Surface Science" 2003, 211, 57-67.

- G. A. Risha, S. F. Son, R. Yetter, V. Yang and B. Tappan, "Proceedings of the Combustion Institute" 2007, 31, 2029-2036.

- X. Zhu, M. Schoenitz and E. L. Dreizin, "The Journal of Physical Chemistry C" 2009, 113, 6768-6773

- C. Badiola, R. J. Gill and E. L. Dreizin, "Combustion and Flame" 2011, 158, 2064-2070

- T. R. Sippel, T. L. Pourpoint and S. F. Son, "Propellants, Explosives, Pyrotechnics" 2013, 38, 56-66

- G. A. Risha, J. L. Sabourin, V. Yang, R. A. Yetter, S. F. Son and B. C. Tappan, "Combustion Science and Technology" 2008, 180, 2127-2142

- S. Rossi, E. L. Dreizin and C. K. Law, "Combustion Science and Technology" 2001, 164, 209-237

- L. Ernst, F. Dryer, R. Yetter, T. Parr and D. Hanson-Parr, "Proceedings of the Combustion Institute" 2000, 28, 871-878

- Y. Gan and L. Qiao, "Combustion and Flame" 2011, 158, 354-368.

- Cheng Zhipeng, Yang Yi, Wang Yi, Li Miaomiao and Li Fengsheng, "Acta Physico-Chimica Sinica" 2008, 23, 152-156

- C. Kong, D. Yu, Q. Yao and S. Li, "Combustion and Flame" 2016, 165, 11-20.

- Zeng Liang in "Study on the Influence of Core-Shell Structure Aluminum Powder on the Reaction Process of Aluminized Explosives," Beijing Institute of Technology, 2011.

- Zeng Liang, Jiao Qingjie, Ren Hui and Zhou Qing, "Journal of Beijing Institute of Technology" 2012, 2, 020.

- B. Rufino, F. Boulc’h, M.-V. Coulet, G. Lacroix and R. Denoyel, "Acta Materialia" 2007, 55, 2815-2827.

- Wang Zhiyong, Peng Chaoqun, Wang Richu, Wang Xiaofeng and Liu Bing, "Journal of Inorganic Materials" 2013, 28, 171-176

- Lu Yuan, Li Jinglong, Yang Jianfeng and Li Peng, "Journal of Inorganic Materials" 2015, 30, 277-281.

- Li Jiguang, Sun Xudong, Zhang Min, Li Xiaodong and Ru Hongqiang, "Journal of Inorganic Materials" 1998, 803-807.